The brake master cylinder is the heart of every vehicle’s braking system. When it starts to fail, stopping power drops, pedal feel changes, and safety quickly disappears. In this guide, I’ll show you exactly how to test if a brake master cylinder is bad—with practical, proven steps that work both in a professional shop and at home.

To test if a brake master cylinder is bad, start the engine and press the brake pedal firmly for about one minute. If the pedal slowly sinks or loses pressure, the internal seals are likely leaking. Check for visible brake-fluid leaks or a dropping fluid level—both indicate a failing master cylinder. For a complete check, perform an internal-leak test or a non-removal pressure test.

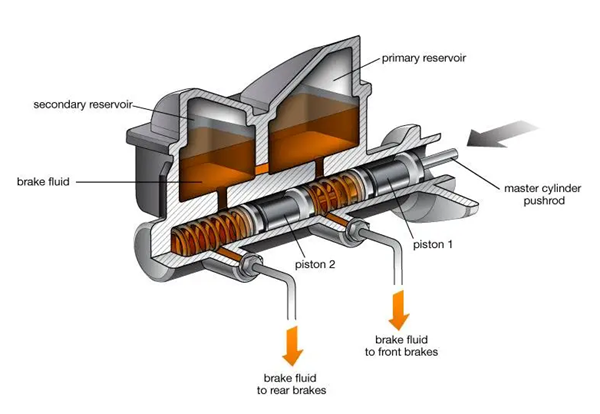

What Does a Brake Master Cylinder Do?

The brake master cylinder converts the mechanical pressure from your foot into hydraulic pressure that activates the brakes on each wheel. Inside the housing are pistons and rubber cup seals that push brake fluid through the lines when you press the pedal.

If these seals wear out, fluid can bypass them internally, which prevents full pressure from building. That’s when the pedal feels spongy or gradually sinks under steady pressure.

In short, the master cylinder’s health determines how firm, stable, and responsive the brake pedal feels.

A failing master cylinder isn’t just inconvenient—it’s dangerous. If it leaks internally, you might suddenly lose braking ability when you need it most. That’s why early testing is essential.

How to Test If Brake Master Cylinder Is Bad (Step-by-Step)

Before getting into the testing steps, let’s quickly look at what you’ll need to perform a reliable diagnosis. Having the right tools on hand not only saves time but also ensures your results are accurate.

Tools You’ll Need

- Safety gloves and eye protection

- A flashlight or work light

- A clean rag and paper towels

- Brake fluid (DOT 3, 4, or 5.1 as specified)

- Line plugs or rubber caps for sealing ports

- A small wrench set

- Optional: brake-pressure gauge (for professional shops)

Once you have these tools ready, you can confidently begin testing. The following steps are suitable for both professionals and DIY users, helping you achieve precise results.

Step 1: Preparation and Safety

Before starting, park the vehicle on level ground, engage the parking brake (or shift into Park), and allow the vehicle to cool down.

- Make sure the brake fluid is at the right level, between the “low” and “full” marks on the reservoir.

- If it’s dark or smells burnt, replace it before testing.

- Keep the reservoir cap on tight when not checking, as brake fluid absorbs moisture easily.

Also, inspect the area around the master cylinder for leaks or dampness, especially near the brake-line fittings. A quick wipe-down helps you spot new leaks later during the test.

Step 2: The Brake-Pedal Pressure Hold Test

This is the easiest and most revealing test for internal seal failure.

- Start the engine to activate the brake booster.

- Press the brake pedal firmly and hold steady pressure.

- Maintain pressure for at least one full minute.

What you should observe:

- If the pedal stays firm, your master cylinder is likely fine.

- If it slowly sinks, fluid is leaking internally past the piston seals.

- If it drops quickly, suspect an external leak before blaming the master cylinder.

Repeat this test once with the engine off. A sinking pedal both with and without vacuum assist nearly confirms an internal leak in the master cylinder.

Step 3: Brake-Fluid Leak Inspection

Even small leaks will compromise brake pressure.

- Inspect the rear section where the master cylinder connects to the booster. The presence of brake fluid in this area typically indicates a leak in the rear seal.

- Inspect all brake-line connections and surrounding areas for moisture or rust stains.

- Watch the reservoir level while pressing the pedal several times; if it drops quickly, you leak.

Tip: Use your flashlight to check under the booster—brake fluid there signals internal leakage from the rear seal.

Step 4: Internal Leak Test

This method isolates the master cylinder completely for a clear diagnosis.

- Brake line off the master cylinder.

- Plug the outlets with rubber caps or threaded plugs.

- Brake pedal down and held.

If the pedal still sinks, fluid is bypassing the internal seals—your master cylinder is bad.

If the pedal stays rock-solid, pressure loss is likely elsewhere in the braking system, such as calipers or wheel cylinders.

This test provides the most direct evidence of an internal fault.

Step 5: At-Home Method

You don’t need fancy tools to test your master cylinder at home:

- Start the car and lightly pump the brake pedal three times to build pressure.

- Hold it steady for about 60 seconds.

- Observe the pedal height.

If it gradually drops, internal leakage is likely.

If it stays firm but feels bouncy, there could be air in the lines—bleed them and retest.

It’s simple, quick, and safe, as long as the car is in park and on level ground.

Step 6: Non-Removal Pressure Test

In a workshop, technicians may use a brake-pressure gauge to measure exact output pressure.

- Attach the gauge to the master-cylinder outlet.

- Press the brake pedal slowly and watch the pressure reading.

- Compare it with factory specs (typically 800–1200 psi for most cars).

If the pressure fluctuates or fails to reach the correct range, your master cylinder cannot generate a consistent hydraulic force, confirming seal failure.

Step 7: Confirm Results and Recheck

After finishing, top off the brake fluid and bleed any trapped air from the system.

Start bleeding from the farthest wheel and move closer to the master cylinder.

Recheck the pedal feel once done—a properly functioning master cylinder should deliver a firm, steady response every time.

Tips to Avoid Misdiagnosis

It’s easy to misread brake symptoms, especially when multiple components are involved. To stay precise:

- Always bleed the brakes first—air in the lines can mimic a bad master cylinder.

- Inspect the brake booster—a hard pedal with poor assist isn’t a master issue.

- Check calipers and wheel cylinders—fluid leaks here can drop pedal pressure.

- Test when hot and cold—some master cylinders fail only after heat expansion.

- Use clean fluid—contaminated fluid damages seals and causes false symptoms.

By cross-checking these factors, you’ll avoid unnecessary part replacements and provide more professional service to your customers.

Summary

Diagnosing a brake master cylinder isn’t about guessing—it’s about observation, consistency, and logic.

By following these structured steps—pedal hold test, leak inspection, internal isolation, and non-removal pressure testing—you can confidently identify a failing master cylinder.

Remember:

- A sinking pedal under constant pressure = internal leak.

- Visible brake fluid around the booster = rear seal leak.

- Low pressure output on the gauge = worn seals.

- Soft pedal even after bleeding = master cylinder failure.

Understanding how to test if brake master cylinder is bad helps you protect customers, prevent brake failures, and build credibility as a true professional.