Clutch Slave Cylinder Manufacturer

OE Performance

GBRAKE Clutch Slave Cylinders – Factory Direct, China Top Quality, Good Price.

China Clutch Slave Cylinder Manufacturer

GBRAKE is a trusted clutch slave cylinder manufacturer in China, providing high-quality solutions for Japanese, Korean, European, American, and Chinese vehicles. In addition to clutch slave cylinders, we also specialize in brake master cylinders, brake wheel cylinders, and clutch master cylinders.

Our factory has successfully passed TRW’s strict factory audit, and all production lines have been upgraded and calibrated according to their high standards. Every GBRAKE clutch slave cylinder is manufactured under OE-level requirements, from precision machining to quality control, ensuring stable performance, smooth operation, and a perfect fit.

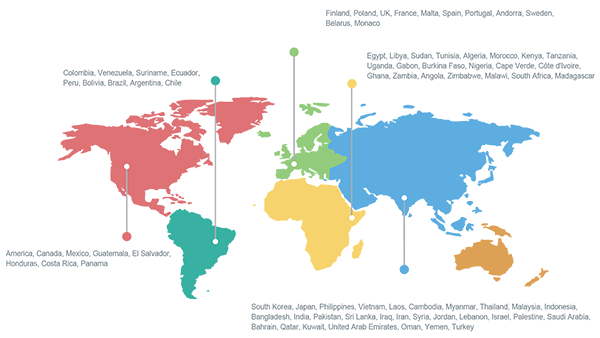

With a reputation for OE-quality and competitive pricing, GBRAKE is widely recognized by customers in South America, Europe, the Middle East, Southeast Asia, and Africa. Our clients trust not only the quality of GBRAKE clutch slave cylinders but also our quick delivery, personalized support, and professional advice that help their business thrive.

If you are looking for the best clutch slave cylinder supplier, GBRAKE offers factory-direct pricing, professional guidance, and personalized support to ensure your business runs smoothly. Don’t wait, let GBRAKE be your trusted partner in success!

GBRAKE Clutch Slave Cylinders

With over 20 years of experience in clutch system components, GBRAKE delivers high-quality clutch slave cylinders you can rely on. We select premium materials and continually refine our production process to ensure smooth operation, long service life, and precise fit. This dedication makes GBRAKE one of the most trusted clutch slave cylinder suppliers in China.

Precision-Machined Cylinder

Ensures smooth and consistent piston movement for reliable clutch operation.Durable EPDM or NBR Seals

Resistant to heat, oil, and hydraulic fluid, preventing leaks and extending service life.OE-Standard Fit

Perfect alignment and compatibility with your vehicle for seamless clutch engagement.Corrosion-Resistant Surface

Protects against rust, moisture, and road conditions, maintaining long-term performance.Responsive Clutch Action

Provides quick, smooth pedal response for safe and efficient gear shifts.

How We Control Quality?

Selected Raw Materials

From the piston, the dust cover, and return spring to the cylinder body, every part of a GBRAKE clutch slave cylinder is made from carefully selected materials to guarantee smooth performance and long-lasting reliability.

Accurate Machining

Each GBRAKE clutch slave cylinder is crafted with CNC precision for a perfect fit and flawless performance. Smooth bores, accurate dimensions, and tight tolerances ensure reliable operation and long-lasting quality you can count on.

Rigorous Testing

Pressure Resistance Tester

Sealing Performance tester

Performance Tester

Durability Tester

Every GBRAKE clutch slave cylinder goes through strict testing, not only during production, but again before final shipment. We check every detail, from sealing performance to piston movement, to make sure every piece works perfectly. Only products that pass all inspections are packed and shipped, so you receive clutch slave cylinders that are completely free from defects and ready to sell confidently.

Industry Certification

Quality Certification

IATF16949

ISO9001

ISO14001

ISO45001

Our factory is certified with IATF 16949 and ISO quality management systems, which means every process follows strict international standards. You can place your bulk orders with complete confidence — GBRAKE is a certified and trusted manufacturer that takes quality seriously from start to finish.

GBRAKE Clutch Slave Cylinder Factory

About GBRAKE

Founded in 2002, GBRAKE specializes in manufacturing hydraulic brake and clutch cylinders in Wuhu City, Anhui Province. Our core products are master and wheel brake cylinders, clutch master and slave cylinders, meeting global market demands.

With a 20,000㎡ production area, GBRAKE operates advanced CNC workshops and testing labs to guarantee high-quality products. Supported by more than 120 skilled workers and a monthly output of around 100,000 pcs, we ensure both strong production capacity and consistent quality for every order.

At GBRAKE, we believe in direct cooperation. By working straight with the factory, you avoid middlemen and hidden costs while enjoying competitive pricing, stable quality, and flexible service. Whether you need a large-volume supply or customized production, our team is ready to respond quickly and support your business growth.

We’d be glad to have you at our Wuhu factory — come and see how GBRAKE turns precision, reliability, and passion into every clutch and brake component we produce.

Clutch Slave Cylinder Production Process

Material Selection

Precision Machining

Honing the Cylinder Bore

Surface Treatment

Ultrasonic Cleaning

Assembly

Testing

Inspection and Marking

Packaging

Shipping

Our Services

Low MOQ

100pcs/model

Competitive Price

Factory Direct Selling

Quality

OE Standard

Warranty

1 Year

Delivery Time

45-50 Days

Full Range of Products

Our clutch slave cylinders cover over 1,000 different models, fitting a wide range of vehicles from Japanese, Korean, European, and American brands. This includes cars, trucks, forklifts, trailers, vans, and light commercial vehicles. Working with GBRAKE, you can find almost any model you need in one place, making it easier to meet customer demands, expand your inventory, and save time sourcing parts.

OEM & ODM Service

Looking to expand your brand? GBRAKE offers complete OEM and ODM services for clutch slave cylinders. We can customize logos, packaging, and develop new cylinders based on your samples. With our years of manufacturing experience, every product meets OE quality standards and fits your market requirements. Partnering with GBRAKE makes it easy to grow your brand and offer reliable, high-quality parts to your customers.

After-Sales Service

At GBRAKE, our support continues long after your order is delivered. If any clutch slave cylinders have quality issues within one year, just send us photos, videos, and the affected quantity. Our team will quickly review and provide prompt solutions or compensation. We stand behind every cylinder we make, ensuring you can sell with confidence and rely on dependable after-sales support for your customers.

Global Market Experience

GBRAKE clutch slave cylinders are trusted by customers in over 100 countries across South America, the Middle East, Southeast Asia, Africa, and Europe. With rich experience in global markets, our team understands the big demands of each region. We provide professional guidance, practical solutions, and reliable support to help your business grow confidently and meet the needs of your customers worldwide.

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.

FAQ of Clutch Slave Cylinders

What is a clutch slave cylinder?

A clutch slave cylinder is a small but important part of a vehicle’s clutch system. It helps control the movement of the clutch, making it easier for drivers to change gears smoothly. Even though it’s compact, its quality and reliability are essential for safe and consistent vehicle operation.

What is included in a clutch slave cylinder?

A clutch slave cylinder is made up of a few key parts that work together to move the clutch. It usually includes:

- Cylinder body – the metal housing that holds all the components inside.

- Piston – sits inside the cylinder and transfers the fluid pressure to the clutch fork, helping it move smoothly..

- Rubber seals and dust boots – keep the hydraulic fluid from leaking and protect the inside from dirt.

- Return spring – helps the piston go back to its original position after you release the clutch pedal.

- Bleeder screw – used to remove air from the hydraulic system during installation or maintenance.

What does a clutch slave cylinder do?

The clutch slave cylinder is the part that helps you disengage the clutch when you press the clutch pedal. When you step on the pedal, hydraulic fluid from the master cylinder flows into the slave cylinder. This pressure pushes the piston inside the slave cylinder, which then moves the clutch fork and separates the clutch from the engine.

In simple terms, it turns the pressure from your foot into movement that allows you to change gears smoothly.

symptoms of a bad clutch slave cylinder

When a clutch slave cylinder starts to fail, your car will usually show a few clear signs. Here are the most common ones:

- Difficulty shifting gears – It becomes hard to change gears smoothly, especially when going into first or reverse.

- Mushy clutch pedal – The clutch pedal feels too soft or sinks to the floor without resistance.

- Fluid leaks – You may notice brake fluid leaking around the transmission area or near the slave cylinder.

- Low clutch fluid level – The reservoir keeps losing fluid, often because of internal or external leaks.

- Clutch not disengaging fully – The car may creep forward even when the clutch pedal is pressed down.

How much clutch slave cylinder replacement cost?

The cost of a clutch slave cylinder mainly depends on its type and quality.

- Aftermarket parts – Usually the most affordable option, priced around $20–$50 depending on the vehicle model and material quality.

- OEM parts – Produced by manufacturers who also make components for car brands. They offer reliable quality at a moderate price, usually between $60 and $120.

- Genuine/original parts – Directly from the vehicle brand, often the most expensive, ranging from $120–$250 or more.

If you purchase directly from a reliable clutch slave cylinder factory in China, the cost can be much lower, around $10–$20/pc, especially for bulk orders. It’s a cost-effective way to get high-quality parts without compromising performance.