Whoelsale Clutch Master Cylinder Manufacturer

Factory Direct Selling

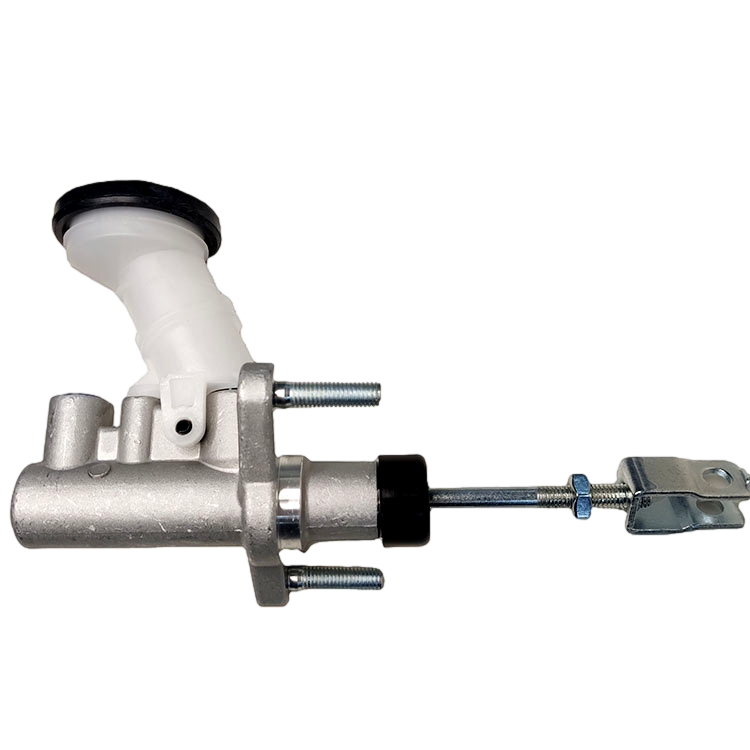

GBRAKE offers both aluminum and cast-iron clutch master cylinders, meeting strict OE standards with a smooth surface finish and precise dimensions to ensure a perfect fit and reliable performance.

China Clutch Master Cylinder Manufacturer

GBRAKE is a trusted clutch master cylinder manufacturer with over 20 years of experience in producing brake and clutch hydraulic parts, including brake master cylinders, wheel cylinders, clutch master cylinders, and clutch slave cylinders.

With thousands of models covering Japanese, Korean, European, and American vehicles, we’ve got nearly every application you need. Can’t find your model? No problem! Our factory offers free development services to meet your specific requirements.

Supported by TRW factory audit approval, every GBRAKE clutch master cylinder is produced under strict OE standards, with precise dimensions and premium materials to ensure long-lasting performance.

We don’t just compete on quality — we also offer the most competitive prices for new customers to experience our products.

Partner with GBRAKE today and grow your business with reliable quality and factory-direct prices!

GBRAKE Clutch Master Cylinders

As a professional clutch master cylinder manufacturer with over 20 years of experience, we focus on precision, durability, and appearance, ensuring every clutch master cylinder not only performs like an OE part but also looks just as refined. That’s how GBRAKE has earned its reputation for stable quality, reliable performance, and exceptional craftsmanship among clutch master cylinder suppliers in China.

Smooth Inner Bore

Provides stable hydraulic pressure and smooth pedal feel without sticking or drag.Precision Piston Movement

Ensures quick response and accurate clutch engagement every time.Corrosion-Resistant Finish

Special surface treatment prevents rust and extends the lifespan of the cylinder.Reliable Sealing System

Keeps the hydraulic system leak-free and maintains consistent pressure.OE-Style Mounting & Connections

Match the original specifications for a direct, hassle-free replacement.

How We Control Quality?

Selected Raw Materials

We only use high-grade raw materials from reliable suppliers we’ve worked with for years. Every batch is strictly tested for strength, purity, and corrosion resistance to ensure each GBRAKE clutch master cylinders stay strong under pressure and delivers stable performance for the long run — no deformation, no leakage, just lasting quality you can trust.

Accurate Machining

Each key part from the piston to the cylinder bore is crafted with precision on advanced CNC machines. We keep every detail within tight tolerances to ensure a perfect fit, smooth movement, and stable hydraulic pressure. So our GBRAKE clutch master cylinders perform just like the original — reliable, consistent, and built to last.

Rigorous Testing

Pressure Resistance Tester

Sealing Performance tester

Performance Tester

Durability Tester

Before leaving the factory, every clutch master cylinder is tested again and again — for pressure strength, sealing, and long-term durability. Only the ones that pass every test make it to our customers. This way, you get a product that delivers stable performance, strong hydraulic power, and zero leakage from day one.

Industry Certification

Quality Certification

IATF16949

ISO9001

ISO14001

ISO45001

At GBRAKE, every step of production follows ISO and IATF16949 quality standards. From the production machine to our factory, we make sure every detail meets international requirements, giving our customers complete confidence in the safety, reliability, and long-lasting performance of every clutch master cylinder we deliver.

GBRAKE Clutch Master Cylinder Factory

About GBRAKE

GBRAKE Auto Parts, based in Wuhu City, Anhui Province, is a trusted manufacturer specializing in brake and clutch cylinders. With over 20 years of production experience, we focus on manufacturing wholesale brake master cylinders, drum brake wheel cylinders, clutch master and slave cylinders. We’ve already developed more than 2,000 models and also support custom development based on your samples or drawings.

Our factory covers 20,000㎡ and is equipped with modern machinery and 10 efficient assembly lines. Backed by a skilled team of over 120 workers, we can produce around 100,000 units per month, ensuring both large-volume capacity and consistent, reliable quality.

You’re always welcome to visit our factory and see how GBRAKE turns precision, experience, and passion into products that meet OE standards and help your business grow.

Clutch Master Cylinder Production Process

Material Selection

Precision Machining

Surface Treatment

Honing the Cylinder Bore

Ultrasonic Cleaning

Assembly

Testing

Inspection and Marking

Packaging

Shipping

Our Services

Low MOQ

100pcs/model

Competitive Price

Factory Direct Selling

Quality

OE Standard

Warranty

1 Year

Delivery Time

45-50 Days

Full Range of Products

GBRAKE clutch master cylinders come in a wide variety of models, covering Japanese, European, and American vehicles from passenger cars and trucks to forklifts, trailers, and agricultural machines. With such a complete range, you can easily find everything you need in one place, making your sourcing faster and your business more efficient.

OEM & ODM Service

Want to build your own brand? GBRAKE is here to help. We offer complete customization from printing your logo to designing your own packaging. Work with GBRAKE, and let’s create a brand your customers will trust.

After-Sales Service

When you work with GBRAKE, you can count on reliable after-sales support. If there’s any quality issue within one year of receiving the goods, please share photos, videos, and the quantity involved. Our team will respond quickly and handle compensation without delay. We take responsibility for every product we make, so you can sell with confidence and focus on growing your business.

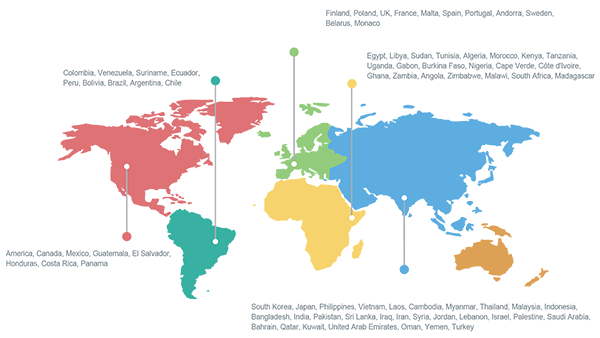

Global Market Experience

GBRAKE has earned the trust of customers in over 100 countries and regions, from South America, Europe, the Middle East to Southeast Asia, and Africa. With years of global market experience, our team understands the different needs of each market and provides practical, professional support to help your business move forward with confidence.

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.

FAQ of Clutch Master Cylinders

What is a clutch master cylinder?

A clutch master cylinder is an essential part of a vehicle’s clutch system. It ensures the clutch works reliably, helping drivers shift gears smoothly and with confidence. A high-quality clutch master cylinder provides consistent hydraulic pressure, giving drivers better control and driving comfort.

What is included in a clutch master cylinder kit?

Our clutch master cylinder kit includes everything you need for a reliable replacement. Each kit comes with a high-quality master cylinder, durable seals and O-rings, necessary mounting hardware, and a push rod or linkage (depending on the model).

clutch master cylinder function

The clutch master cylinder converts the movement of the clutch pedal into hydraulic force to operate the clutch system. This pressure then activates the clutch system, allowing the driver to engage or disengage the clutch smoothly. Essentially, it ensures that gear changes are consistent, controlled, and reliable.

how to tell if clutch master cylinder is bad?

Signs of a Bad Clutch Master Cylinder:

- Soft or Spongy Clutch Pedal – The pedal feels unusually soft, sinks to the floor, or doesn’t return properly.

- Difficulty Shifting Gears – Gear changes become rough or the transmission grinds.

- Fluid Leaks – Brake fluid leaking near the firewall, under the clutch pedal, or around the cylinder itself.

- Low or Contaminated Fluid – The reservoir fluid level drops quickly, or the fluid looks dark and dirty.

- Clutch Pedal Stuck to the Floor – Pedal doesn’t spring back after pressing.

How much clutch master cylinder replacement cost?

Clutch master cylinders are available to suit different budgets and requirements:

- After‑market replacements: Affordable and reliable, typically $30–$70.

- OEM parts: High compatibility and consistent performance, usually $50–$150.

- Genuine parts: Exact factory specifications and maximum reliability, ranging $150–$300+.

For buyers looking to reduce costs, sourcing directly from a reputable Chinese clutch master cylinder factory can bring the price down to as low as $10–$20 per piece for bulk orders, without compromising quality or supply stability.