Brake Wheel Cylinder Manufacturer

OE Performance

GBRAKE hydraulic wheel cylinders feature a smooth finish and precise tolerances that meet OE standards, ensuring a 100% perfect fit, as well as being fluid-, corrosion-, and rust-resistant.

China Brake Wheel Cylinder Manufacturer

GBRAKE is one of the leading brake wheel cylinder manufacturers in China, specializing in high-quality brake wheel cylinders, brake master cylinders, clutch master cylinders, and clutch slave cylinders for Japanese, Korean, European, American, and Chinese vehicles.

Our factory has passed the strict audit by TRW, and all production lines have been upgraded to meet their standards. Every GBRAKE wheel cylinder is made under OE-level requirements, from material selection to precision machining, ensuring stable performance and perfect fit just like the original parts.

With reliable quality and competitive prices, GBRAKE brake cylinders have earned strong recognition from customers across South America, Europe, the Middle East, Southeast Asia, and Africa. Many customers choose GBRAKE not only for our consistent product quality but also for our fast delivery and professional support that help them grow their business in competitive markets.

If you’re searching for a reliable brake wheel cylinder supplier, GBRAKE will support your success. Contact us today for factory-direct pricing, quick response, and one-on-one service that truly understands your needs.

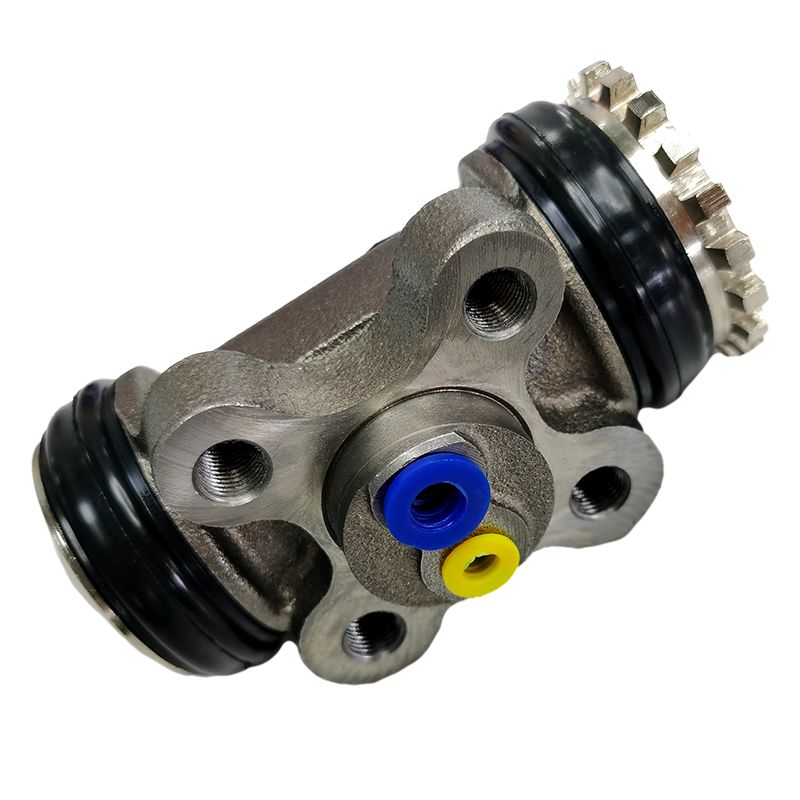

GBRAKE Brake Wheel Cylinders

With over 20 years of experience in brake wheel cylinder production, GBRAKE focuses on quality and precision. We use premium materials and keep improving our process to ensure smooth performance, long life, and a clean finish. That’s why GBRAKE stands out as one of the most trusted brake wheel cylinder suppliers in China.

Anodized Body

Strong and corrosion-resistant surface for smooth piston movement.High-Quality EPDM Seals

Heat- and fluid-resistant rubber prevents leakage and lasts longer.OE-Standard Design

A perfect fit and stable braking, just like the original part.Anti-Rust Coating

Protects against moisture, salt, and road corrosion.Quick Brake Response

Fast reaction to pedal pressure for smooth, safe braking.

How We Control Quality?

Selected Raw Materials

Quality starts with raw materials. We only use high-grade aluminum, iron, and rubber that meet OE standards to ensure strength, durability, and perfect sealing.

Accurate Machining

Every wheel cylinder is processed with advanced CNC equipment for consistent accuracy, guaranteeing smooth inner surfaces, precise dimensions, and a perfect fit, ensuring stable braking performance and long service life.

Rigorous Testing

Pressure Resistance Tester

Sealing Performance tester

Performance Tester

Durability Tester

Before delivery, each brake wheel cylinder goes through multiple inspections, including pressure, leakage, and performance tests. Only products that pass all tests are shipped out, giving you confidence in every order.

Industry Certification

Quality Certification

IATF16949

ISO9001

ISO14001

ISO45001

Our factory owns IATF16949, ISO, and other international quality standards. These certifications prove our ability to deliver stable quality, reliable performance, and professional manufacturing management that meet global market demands.

GBRAKE Brake Wheel Cylinder Factory

About GBRAKE

Since 2002, GBRAKE Auto Parts has established a brake and clutch factory in Wuhu City, Anhui Province, manufacturing brake wheel cylinders, brake master cylinders, clutch master cylinders, and clutch slave cylinders. We’ve developed more than 2,000 models and can also build new ones based on your samples.

Our factory covers 20,000 ㎡ and is equipped with advanced CNC machines, modern assembly lines, and strict testing systems. Backed by 120 skilled workers and a monthly output of around 100,000pcs, we have the strength to support bulk orders with stable quality and reliable delivery.

By choosing GBRAKE, you’re working directly with the factory — no middlemen, no hidden costs. We provide competitive pricing, fast communication, and flexible service to help our partners grow their market and strengthen their brand. If you’re interested in visiting our factory or learning more about our products, we’re always ready to welcome you.

Brake Wheel Cylinder Production Process

Material Selection

Precision Machining

Honing the Cylinder Bore

Surface Treatment

Ultrasonic Cleaning

Assembly

Testing

Inspection and Marking

Packaging

Shipping

Our Services

Low MOQ

100pcs/model

Competitive Price

Factory Direct Selling

Quality

OE Standard

Warranty

1 Year

Delivery Time

45-50 Days

Full Range of Products

Our brake wheel cylinders are available for a wide range of Japanese, European, and American vehicles, including cars, trucks, forklifts, trailers, and agricultural machinery. At GBRAKE, you can find all the models you need in one place, making it easier to meet your market demands and save valuable time.

OEM & ODM Service

Want to grow your brand? GBRAKE makes it simple. We offer full OEM and ODM support, from custom logo printing and packaging to production based on your samples. With years of manufacturing experience, we offer brake wheel cylinders that meet OE quality and fit your market needs. Partner with GBRAKE and take your brand to the next level.

After-Sales Service

When you work with GBRAKE, support doesn’t stop after the sale. If you encounter any quality issues within one year of receiving your brake wheel cylinders, simply provide photos, videos, and the affected quantity, and our team will review and offer fast compensation. We stand behind every brake wheel cylinder we produce, giving you confidence and reliable support in your market.

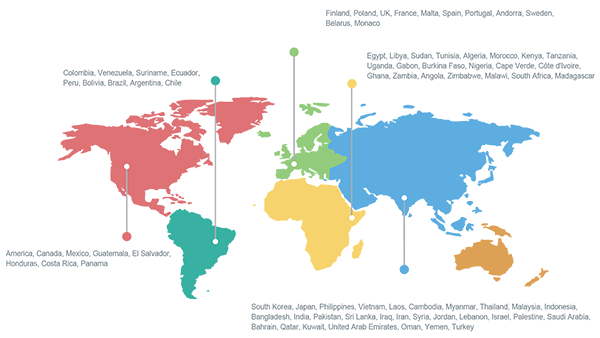

Global Market Experience

We’ve been supplying brake wheel cylinders to customers in more than 100 countries and regions, including South America, the Middle East, Southeast Asia, Africa, and Europe. With years of experience in the global market, our team understands different market demands and is always ready to provide you with the right solutions, professional guidance, and reliable support to help your business expand with confidence.

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.

FAQ of Brake Wheel Cylinders

What is a brake wheel cylinder?

A brake wheel cylinder, also called brake wheel pump, wheel brake cylinder, drum brake wheel cylinder, is a small but important part of your car’s drum brake system. It’s the component that brings the braking force right to the wheels. A well-built wheel cylinder means steady braking performance, smooth pedal feel, and reliable stopping power every time you hit the brakes.

What is included in a brake wheel cylinder?

A brake wheel cylinder is made up of several precision parts that work together to ensure smooth and reliable braking. It typically includes:

Cylinder body – the main housing, usually made of cast iron or aluminum.

Pistons – two pistons that move outward to apply pressure to the brake shoes.

Rubber seals (cups) – prevent hydraulic fluid from leaking and keep pressure steady.

Return springs – help the pistons return to their original position after braking.

Dust boots – protect the inner components from dirt, water, and corrosion.

Bleeder valve – allows air to be removed from the brake system during servicing.

Each part plays an important role in keeping the wheel cylinder durable, leak-free, and performing at its best.

What does a brake wheel cylinder do?

A brake wheel cylinder is in the drum brake system. When you press the brake pedal, hydraulic pressure from the master cylinder travels through the brake lines to the wheel cylinder. Inside, the pistons push outward on the brake shoes, forcing them against the drum to create friction and slow the wheel down.

symptoms of a bad brake wheel cylinder

When a brake wheel cylinder starts to fail, it can cause several noticeable issues in your braking system. Common symptoms include:

- Weak-feeling brake pedal – air or fluid leaks inside the wheel cylinder reduce hydraulic pressure.

- Brake fluid leakage – you may find fluid around the drum or on the inside of the wheel.

- Poor braking performance – the car takes longer to stop or feels unbalanced when braking.

- Brake warning light on – low brake fluid caused by leaks can trigger the warning light.

- Uneven brake shoe wear – one piston may stick or seize, causing one shoe to wear faster than the other.

How much brake wheel cylinder replacement cost?

Prices of brake master cylinders vary depending on the model and specifications. In most local markets, aftermarket units are usually priced around $50–$80, OEM units range from $90–$160, and genuine/original parts can reach $150–$300.

If you buy directly from a reliable brake wheel cylinder factory, the price can be as low as $6–$15 per unit. For bulk buyers, working with a trusted factory is a cost-effective way to get high-quality wheel cylinders with a stable supply and consistent performance.